One talented metal smith made this stunning ring by hand. Seeing the finished ring, it looks beautiful, but it's even more impressive when you know how much effort went into creating it. This ring was made using the Japanese mokume-gane technique. The term "mokume-gane" roughly translates to wood grain and the technique involves fusing many thin sheets of metal to create a pattern similar to wood grain. Sounds difficult? Well, it is! Let's see how it's done!

You start out with thin plates of brass and copper. There needs to be two colors of metal to create the effect.

First the pieces have to be clamped together.

Then they go in a hot furnace known as a crucible.

Once they come out the stack needs to be compressed with 10 tons of pressure.

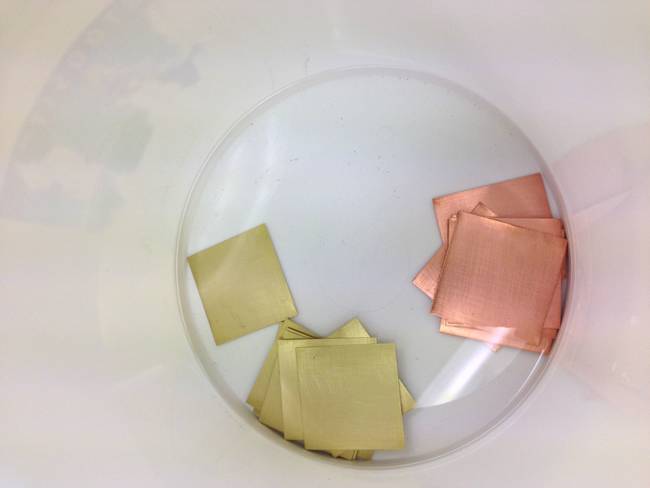

Once released from the clamp, the stack of sheets has fused into one solid piece. Cool! But, there's still a long way to go.

The metal then has to be twisted to create the wood grain effect.

Then the twisted piece has to be heated, cooled and reheated several times to that it becomes malleable enough to shape.

Using tools, the rough shape of a ring can be formed.

After much hammering and sawing, it looks way more like a ring.

Now it just needs to be sanded down and shaped.

And, it's complete! Beautiful!

The process looks painstaking but it's worth the effort to create something so stunning!