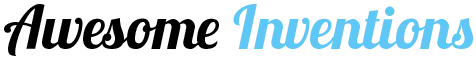

Long before screws and other metal fasteners became staple hardware in woodworking, Japanese wood joinery has been practiced by master craftspeople. This architectural tradition makes use of techniques where builders would fit wooden beams together without the use of metal fasteners or adhesives. Much like sushi-making, calligraphy, and flower arranging, this traditional woodworking practice has been handed down generation after generation. These buildings, held together with nothing more than tension and friction, are still standing for centuries.

Over time, this ancient practice of Japanese wood joinery has mostly fell out of ordinary use. But practitioners of the craft continue to refine the intricate techniques and pass them down to the next generations. So, how does this age-old woodworking practice fit into the digital age? A team of researchers in the University of Tokyo developed a free 3D modelling software which is named after the traditional woodworking practice itself – Tsugite.

Interactive Modeling Software Makes The Art Of Japanese Wood Joinery Easier

View this post on Instagram

Unlike the conventional carpentry that we know now, Japanese wood joinery is the truest test of woodworking skills because builders put up entire structures using only wood. This complex craft involves cutting pieces of wood in such a way that the components fit together as firmly and tightly as possible. It’s essentially like carving intricate wooden joints by hand so the components fit together like pieces of puzzle.

View this post on Instagram

View this post on Instagram

View this post on Instagram

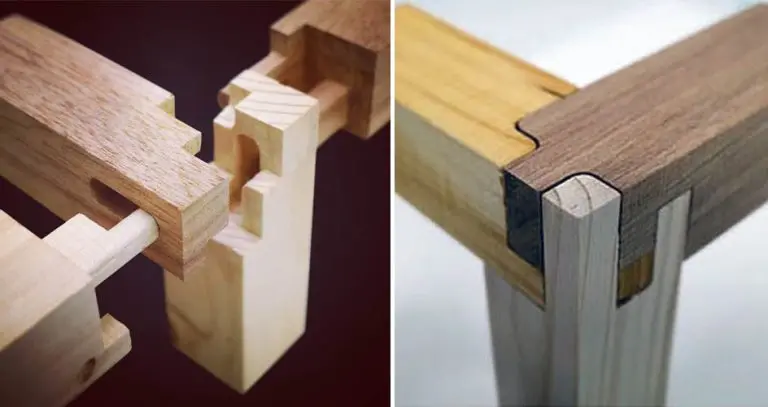

The new software Tsugite is an interactive system that will make it easier to design and fabricate wood joints for frame structures. It combines modeling interface system with computer numerical control (CNC) fabrication to allow users to design and create custom wooden joints. When the design is finalized, it can be manufactured using a 3-axis CNC milling machine.

View this post on Instagram

View this post on Instagram

View this post on Instagram

Users have the option to use two different interface modes: manual editing and gallery. The manual editing mode is geared towards experienced users. In this mode, users can design their own custom joints on a 3D grid of voxels while being assisted by real-time graphical feedback and performance metrics. On the other hand, the gallery mode features a collection of pre-calculated joints allowing novices to simply select predefined feasible joints.

View this post on Instagram

View this post on Instagram

View this post on Instagram

View this post on Instagram

View this post on Instagram

View this post on Instagram

View this post on Instagram

View this post on Instagram

View this post on Instagram

View this post on Instagram

View this post on Instagram

Watch the fascinating process on the video below

You can download the 3D modelling software for free via the project website. The software is available in older and newer versions which are offered free for personal and non-commercial use. You can also follow the research project on Instagram to get some joint design inspirations to help you create functional furniture.